| Home |

| Stirling Engines |

| State of the Art |

| Theory |

LTDS Engine for power generation - C. LLoyd

Source

A low temperature differential Stirling engine for power

generation

Thesis - Caleb Lloyd, University of Canterbury, New Zealand

2009

Characteristics

Type: gamma, controled/powered rotating

displacer

Theoretical power: 500W with Th=90°C and Tc=20°C and working

gas (air) at 10bar

Measured power: na

Beale: expected value 0.002 to 0.008

Vexpansion = 5000 cm3

Vcompression = 83000 cm3

Heater: 43200 cm3 * ?%, wetted area = 8.1m2

Cooler: 43200 cm3 * ?%, wetted area = 8.1m2

Regenerator: modular, 43200 cm3 * x%

Illustrations

Details

www.elec.canterbury.ac.nz - [ pdf ]

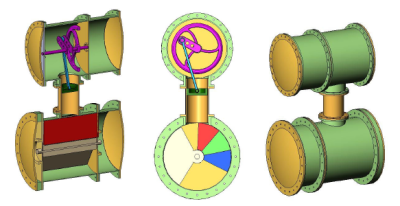

This Gamma-type piston engine has not been tested yet. The

geometry is not usual, mainly the displacer chamber, with an

rotating displacer. The engine is supposed to oscillate at 2 Hz

with working gas at 10bar pressure.

The piston is made of aluminum, it is constructed with separate pieces bolted together for cost reduction reasons. The seals are silicone rubber O-rings, lubricated with silicone grease.

The displacer is oscillating in a rotation movement, it is actuated by a motor to be able to vary velocity parameters. Once the optimal motion will be determined, the electrical actuation will be replaced by an appropriate mechanical linkage. The displacer is made of expanded polyurethane foam and an aluminum framework.

Heater and cooler are base on fin-tube structures. Fins are made of aluminum, and the tubes are made of copper

The regenerator is a modular element that can be pulled out and changed easily. Regenerator and heat exchangers have the same dimensions. Six different material have been studied for the regenerator. The best results are obtained with mild steel wool.

| Material | Fiber diameter [micrometers] |

Density [g/cc] |

Cp [J/kg°C] | Regenerator effectiveness [%] |

Indicate |

| Mild steel wool | 30 | 7.8 | 437 | 94 | 8.8 |

| Stainless steel wool | 40 | 7.8 | 510 | 79 | 6.6 |

| Stainless steel mesh | 100 | 7.8 | 510 | 85 | 5.3 |

| Silica wool | 7 | 2.2 | 840 | 89 | 6.9 |

| Glass fiber | 1 | 2.7 | 670 | 84 | 4.7 |

| Kao wool | 7 | 2.5 | 1070 | 91 |

2.22 |

(*) tested in a small air test engine

|

State of the Art - index |