| Home |

| Stirling Engines |

| State of the Art |

| Theory |

Stirling Engines History

The

Stirling engine (or Stirling's air engine as it was known at the

time) was invented and patented by Reverend Dr. Robert Stirling in

1816. It followed earlier attempts at making an air engine but was

probably the first to be put to practical use when in 1818 an

engine built by Stirling was employed pumping water in a quarry.

The main subject of Stirling's original patent was a heat

exchanger which he called an "economiser" for its enhancement of

fuel economy in a variety of applications. The patent also

described in detail the employment of one form of the economiser

in his unique closed-cycle air engine design in which application

it is now generally known as a 'regenerator'. Subsequent

development by Robert Stirling and his brother James, an engineer,

resulted in patents for various improved configurations of the

original engine. Their pressurization enhancement had by 1843

sufficiently increased power output enough to drive all the

machinery at a Dundee iron foundry.

The

Stirling engine (or Stirling's air engine as it was known at the

time) was invented and patented by Reverend Dr. Robert Stirling in

1816. It followed earlier attempts at making an air engine but was

probably the first to be put to practical use when in 1818 an

engine built by Stirling was employed pumping water in a quarry.

The main subject of Stirling's original patent was a heat

exchanger which he called an "economiser" for its enhancement of

fuel economy in a variety of applications. The patent also

described in detail the employment of one form of the economiser

in his unique closed-cycle air engine design in which application

it is now generally known as a 'regenerator'. Subsequent

development by Robert Stirling and his brother James, an engineer,

resulted in patents for various improved configurations of the

original engine. Their pressurization enhancement had by 1843

sufficiently increased power output enough to drive all the

machinery at a Dundee iron foundry.

Though it has been disputed, it is widely supposed that as well as saving fuel the inventors were motivated to create a safer alternative to the steam engines of the time, whose boilers frequently exploded causing many injuries and fatalities. The need for Stirling engines to run at very high temperatures to maximize power and efficiency exposed limitations in the materials of the day and the few engines that were built in those early years suffered unacceptably frequent failures (albeit with far less disastrous consequences than a boiler explosion) - for example, the Dundee foundry engine was replaced by a steam engine after three hot cylinder failures in four years.

Stirling Engines

A

Stirling engine is a closed-cycle regenerative

heat engine with gaseous working fluid. A closed-cycle

is defined as a thermodynamic system in which the working fluid is

permanently contained within the system. Regenerative

describes the use of a specific type of internal heat exchanger

having thermal storage, known as "the regenerator" which increases

the engine's thermal efficiency compared to simpler hot air

engines. As an external combustion engine, in which the energy

input to the engine is separated from the working fluid, which

undergoes pressure and volume fluctuations to produce useful work,

Stirling engines can be driven by any heat source.

A

Stirling engine is a closed-cycle regenerative

heat engine with gaseous working fluid. A closed-cycle

is defined as a thermodynamic system in which the working fluid is

permanently contained within the system. Regenerative

describes the use of a specific type of internal heat exchanger

having thermal storage, known as "the regenerator" which increases

the engine's thermal efficiency compared to simpler hot air

engines. As an external combustion engine, in which the energy

input to the engine is separated from the working fluid, which

undergoes pressure and volume fluctuations to produce useful work,

Stirling engines can be driven by any heat source.

The Stirling cycle is notable for its perfect theoretical thermal efficiency; however this as yet unrealized ideal remains an immense engineering challenge. Nevertheless, current designs are noted for their high efficiency, quiet operation and the ease with which they can utilise what would otherwise be waste heat. The Stirling engine is currently exciting interest as the core component of domestic combined heat and power (CHP) units, which could have a significant effect upon worldwide energy consumption.

The Stirling engine has been used in low-power applications for nearly two centuries. Stirling engines continue to be used as they can provide mechanical or electrical power, heating or cooling in applications wherever a heat source and heat sink are available.

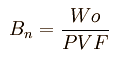

Beale Number

Beale

number is a parameter that characterizes the performance of the

Stirling engine. It is usually used to estimate the power output

of a Stirling engine design.

Beale

number is a parameter that characterizes the performance of the

Stirling engine. It is usually used to estimate the power output

of a Stirling engine design.

Beale and coworkers stated that the measured power of stirling engines is proportional to the product of some simple parameters, the proportionality coefficient is now referred as the Beale number (Bn), and it is dependent on the design geometry.

where:

* Bn is the Beale number

* Wo is the power output of the engine [watts]

* P is the mean average gas pressure [Pa]

* V is swept volume of the expansion space [m3]

* f is the engine cycle frequency [Hz]

Typical values for the Beale number are 0.11 to 0.15 when considering high temperature differential engines

For LTDS some values have been published:

B. Kongtragool, University of Technology Thonburi, Bangkok:

Bn = 0.0025

The Regenerator (Economizer)

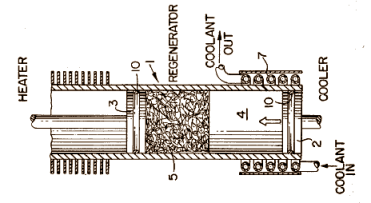

The

regenerator is actually the main improvement that Robert Stirling

introduced to achieve the developpement of previous attempts at

making "hot air engines". R. Stirling used this heat exchanger to

take up a part of the energy of hot gaz leaving the expansion

chamber and to deliver this energy when the cold gaz goes back to

the expansion chamber. This device avoid some loss of energy, at

that time it was called the "economizer".

The

regenerator is actually the main improvement that Robert Stirling

introduced to achieve the developpement of previous attempts at

making "hot air engines". R. Stirling used this heat exchanger to

take up a part of the energy of hot gaz leaving the expansion

chamber and to deliver this energy when the cold gaz goes back to

the expansion chamber. This device avoid some loss of energy, at

that time it was called the "economizer".For beta and gamma configuration the regenerator can be included in the displacer piston, as it was the case for the very first engine built by Rev. Robert Striling in 1818.

Many studies have focused on this particular element of stirling engines. Nevertheless, modelling the behaviour of a particular regenerator is not a trivial work. The optimization of the regenerator involve both dynamic thermal exchanges and unsteady fluid flow considerations.

Some example of regenerators:

- Stainless steel wire cloth (http://www.bekkoame.ne.jp/~Akhirata/academic/kiriki/nse/nsestrct.html)

- Laminated brass mesh cloth (http://www.bekkoame.ne.jp/~khirata/academic/kiriki/expse/index.html)

- Brass Wire Cloth (http://www.bekkoame.ne.jp/~khirata/academic/kiriki/yama1/300strct.html)

- Laminated Brass wire cloth (http://www.bekkoame.ne.jp/~khirata/academic/kiriki/solar/kozo.html)